267. Peterson Rustication, Part 1: the Éire through Dublin Eras

When I went through my rotation not long ago, I was struck by how many rusticated Petes I companion. I hadn’t realized the extent of my fascination and love for these pipes, so often ignored or underrated by the Cognoscenti of Pipe Fashion.

In the past, Peterson Pipe Notes has looked at the rustication history of the Donegal Rocky and the Laudisi-era launch of the rustic Arans and Rosslares, but this morning I want to contextualize an upcoming interview with current K&P rustication craftsmen (and brothers) Wojciech & Jaroslaw Blaszczak. I thought it might be time to gather together what I know about the company’s long history of rustication, at least in a tentative way. As you read through, take thought of your own rusticated Petes and let me know if you information, facts, opinions and pipes that can further our understanding. But first, a PSA (Peterson Service Announcement):

The 1896 Peterson’s Patent Pipes Catalog AND the new paperback of Peterson Pipes: The Story of Kapp & Peterson are now available at SPC. “Get yours while supplies last!”

The rusticated pipe is often treated like an ash-heap Cinderella, the sister who hides when the beautiful natural smooth or ring-grain blasts come out. It’s impossible to disparage these girls, who were after all elegant, high-class beauties in the original Perrault and Grimm tellings of the story. But I want to advocate a bit for the gnarly beauty, punk tactility and sheer surly invention possible in a well-rusticated pipe, not least because I call a number of them friends.

I’m not alone in my love of the rough pipes, I’m glad to say, as elder statesmen in the hobby like John P. Seiler and William D. Kotyk in their classic NASPC article “We Like Them Rough” championed not only rusticated pipes but the deep sandblasts that were then fairly new to the scene [PDF: Seiler_rough ]. Another guru worth mentioning in this regard is Doctor of Pipes Linwood Hines (founder of CORPS, the Conclave of Richmond Pipe Smokers and Richmond Pipe Show), who once in a while inducts members into “The Fellowship of Gnarly Briars,” a kind of Southern Comfort-Style secret society of aficianados of all pipes gnarly.

If the history of rustication at K&P is sketchy, it’s because these pipes were not seen as important in the scheme of things: they occupied the lower tiers and existed primarily to avoid taking a loss on the briar. So there is very little known about the process in the factory—who did it, when they did it, when it began. Like sandblasting, we do know why it began, as I just implied: to rescue bowls from discard and the company from a financial loss.

When sandblasting finally came into its own about twenty years ago through the agency of American blasters like J. T. Cooke and others, there was a look over the shoulder to old factory masters like Dunhill and newer ones like Castello to give artisan blasting a whiff of “apostolic succession” authority. With rusticating, however, there are no prestigious prophets to bear witness, are there? Fortunately for us, K&P (as in most areas of its history) just went along its business, content to do things the Irish way.

In the decade or so I’ve been researching all things Peterson on a more or less daily basis, I haven’t come across a single Patent or Irish Free State rusticated pipe, so I doubt there were any. During those years, K&P dealt with bowls through putty (like the Grade 4 Systems) or seconds (the K&P Dummies line), there being no other way at the time to utilize the paid-for bowls. 1

THE CRAFT OF RUSTICATION

Handmade rustication tool (Pipedia)

Rustication can be done with virtually any type of sharp tool found in the shop, although many pipe makers prefer to create their own. Tony Fillenworth, an artisan in Illinois, has a great article on the basic methodology, as does Pipedia, both of which are worth a read. At Reborn Pipes, Steve Laug explains how you can make your own, with the added benefit that you can see had he gone over the pipe a few more times, it might have transformed from merely rustic to awesomely rustic.

Daniela Cavicchi’s rustication tool

A Daniela Cavicchi-rustication from 2012

Fillenworth uses both a homemade gouger-type hand tool as well as a Dremel. Daniela Cavicchi, who did the rustication for her husband Claudio Cavicchi’s pipes back when he offered them, also used a homemade tool.

This rusticated hawkbill by Dr. Robert Kiess of Dr Bob Pipes has a unique rustication that has earned him many enthusiastic customers. Like other artisans, Dr. Kiess has created his own rusticating equipment.

Even more than sandblasting, rustication gives a pipe a very individualized look so that pipes rusticated by one artisan will rarely look like those done by another unless an effort has been made (as in Castello’s factory setting) to use the same tool or tools in the same way. The actual process of gouging or rusticating the wood, depending on which artisan or craftsman you ask, seems to vary from five to eight or nine minutes. In other words, you can almost plot the depth and texture from shallow to deep, simple to complex with your stopwatch.

Castello Sea Rock Panel (2022)

For K&P, I think it’s safe to lay down two hard-and-fast facts about their rustication history: (1) hand rustication not only changes by era but sometimes several times within an era; (2) as documented by craftsmen at the factory in 2013, hand rustication has often been done by a single individual and sometimes more than one at the same time. As most pipemen know the Castello Sea Rock, which more than any other line has established itself in the hobby as the standard against which to measure all rustication, we’ll use it as a baseline against which to explore K&P’s efforts over the decades.

PATENT AND IRISH FREE STATE ERAS

In the decade or so I’ve been researching all things Peterson on a more or less daily basis, I’ve never heard about or run across a single Patent or Irish Free State rusticated pipe, which makes me think there probably weren’t any. During those years, K&P dealt with bowls through putty (like the Grade 4 Systems) or seconds (the K&P Dummies), there being no other fashion to utilize the paid-for bowls. 1

ÉIRE (1938-1948)

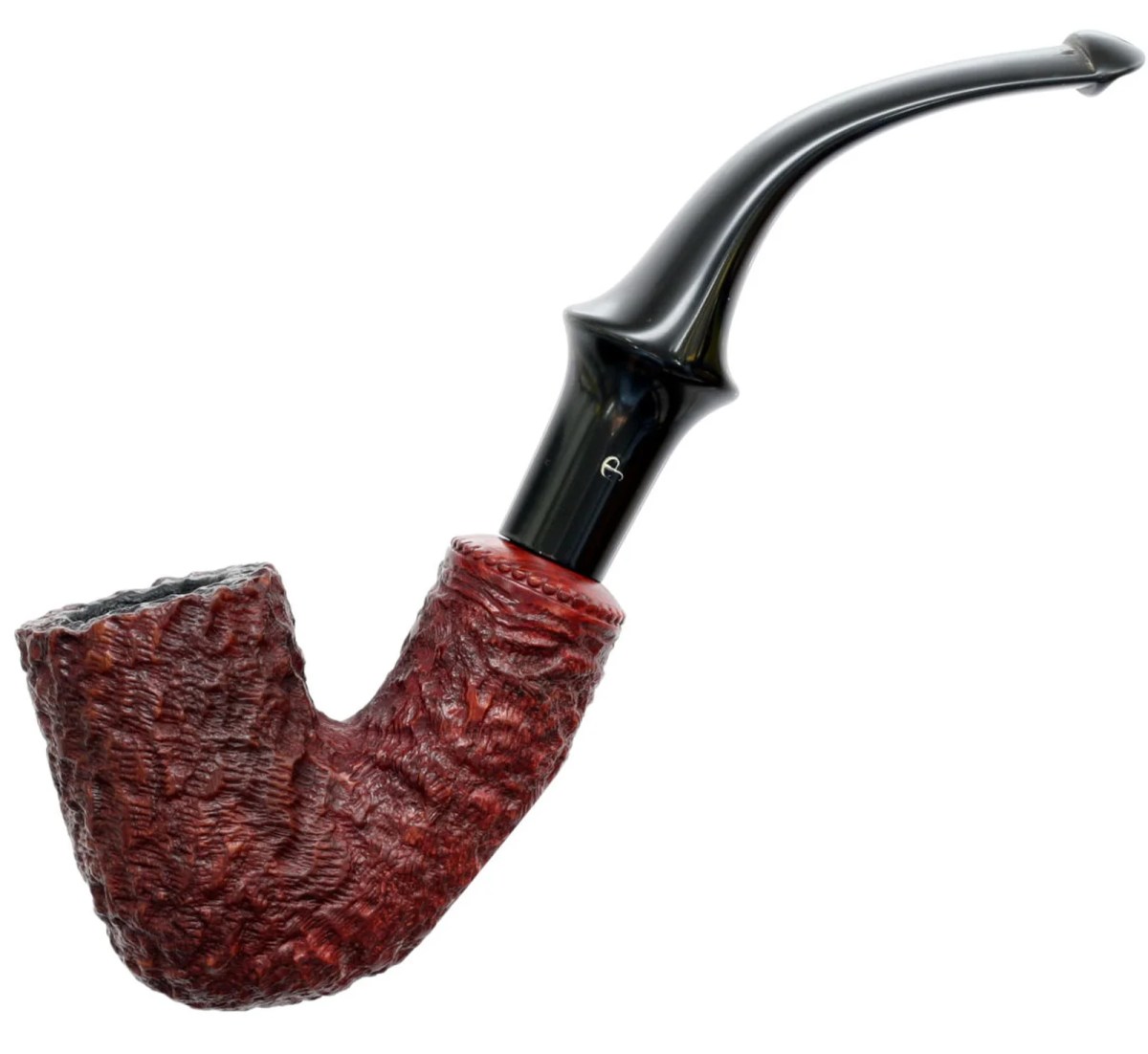

Éire 363

Here’s the earliest K&P rustic I’ve documented so far: a 363 Grade 3 (shape 8 / 313). Was it done with a chisel or a drill? I don’t know. Any thought? In any event, I’ve seen none like it.

In its first catalog appearance from 1945, the Donegal Rocky wore the black coal-like rusticated finish with a sterling band (using the K & P in shields Maker’s Mark) and a F/T stem.

Rustication at Kapp & Peterson came into its own at the end of WWII, when supply chain issues became a thing of the past and world demand for pipes soared. In 1945, for the first time in the company’s then-70 year history (they counted back to 1875 in those days), a new line was issued for rustic pipes: the Donegal Rocky. I wouldn’t push this in the noses of Castello Sea Rock fans, but just between you and me, Kapp & Peterson got there first. The Sea Rock didn’t debut until 1947, two years after the Donegal Rocky. 2

The only late Eire / Early Republic Donegal Rocky I’ve seen in the wild, an 02 Oom Paul. The lack of a MITROI stamp is fairly convincing evidence that it was made between 1945 and 1948.

If you compare the recent Sea rock with the circa 1950 Donegal Rocky, it looks to me like the Irish win the gnarly MF contest.

Early Republic Long Shank

This long shank Canadian’s rustication is in the same style and possibly by the same craftsman as the 02 Donegal Rocky. For my money, this pattern and style, which is even deeper than the 02, is as strong and muscular as K&P have ever achieved—not as silky as the later Pebble Rustic, not as refined as the work of Castello. Just a gnarly BAMF.

EARLY REPUBLIC (1949-1968)

Early Republic 309

This 309 shows what might have been a transition between the original rusticated finish and what would come in the mid-1950s with larger texture, say, than the shape 11 below but much softer and les craggy than the 02 Donegal above. It could, just the same, have been done by a different craftsman or the same one on a different day of the week (there were between 100 and 120 employees at the Dublin factory during this era). All three rustications are quite deep, but notice they maintain the integrity of their shapes.

Early Republic Shape 11 Stack Kapet

This unusual shape 11 stack is very similar like Carlo Scotti’s Sea Rock texture: craggy, softly rolling and uniform around the bowl, a foreshadowing of the later Pebble Rustic finish and every bit its equal.

DeLuxe 04S

This DeLuxe 04S was made before 1963 (it has a bone tenon). Notice how finely the rustication is done. As you can see along the top rim—in case your eyes try to deceive you—this isn’t a sandblast, but a minutely rusticated surface. I can see why it was given a DeLuxe status. I’ve never seen another DeLuxe Rustic. If you have, or if you own one, do leave a comment and get in touch!

1965 Aran (from 1965 catalog)

The first release of the Aran line in the mid-1960s shows a definite link to the DeLuxe 04 System in the pebble-like rusticating technique.

LATE REPUBLIC (1969-1990)

1975 Aran (catalog): Another great, forgotten XL shape!

1975 Aran (catalog): Another great, forgotten XL shape!

The 1975 Aran rustication looks identical to that from a decade previous.

This shape—the 30S—dates from the first release of the Aran line, which consisted of several XL bowls unique to the line. The rustication isn’t the bituminous coal look of the 1965 or 1975 catalogs, but a little more relaxed (meaning less time was spent on it), making me if it dates from a few years later or someone was just in a hurry.

04 Special Kaffir in Brush Rustic

One of my favorite rustications appeared during the second decade of the Late Republic era. It used a very distinctive vertical striated pattern, one Briarworks picked up on a few years back. It’s amazing under finger and thumb and gives the pipe a tremendous tactility. I can see (or rather, feel) why Briarworks uses it.

A recent Briarworks Bulldog using the same technique and color

The first appearance of the Black Brush Rustic (1978 IRC Catalog)

The first K&P catalog appearance of the Black Brush Rustic (1979 catalog update)

This style—which has never been repeated—appeared first in the 1978 Iwan Ries & Co. catalog then in the following year’s update to the 1975 K&P Orange Catalog, where it was christened the “Black Brush Rustic” of the K&P Dublin. (If the Brothers Blaszczak at the factory are reading this, think about doing a special edition Black Brush Rustic System!)

Dunmore Rustic 79, c. 1975

Dunmore Rustic XL75, c. 1981

Paddy Larrigan’s genius reworked the System line as “setter” pipes, balancing on the button and the flattened bottom of the shank. The Dunmore line appeared first for Iwan Ries in 1971, then following its success was released worldwide. The rustication in the examples I’ve seen are similar but not identical. The 79 above probably dates from the early to mid-1970s. Notice the tiny straight lines almost like a chisel with little sharp teeth, indicating a different type of rusticating tool than seen elsewhere in the K&P catalog. The XL75, however, looks a bit more like a flattened Castello Sea Rock and actually seems to be from the same craftsman who made the Donegal Rocky XL339 below.

Donegal Rocky Rustic 01, 1979

In between the two Dunmores, and again right there at the height of K&P’s genius in the late 1970s and early 1980s, was the most glam of all the Donegals. This 01 was released the very year the shape hit the market (or at least the catalog update): it had the old aluminum stinger, a slide-in-slide-out affair meant to offer a cooler smoke and dating from the 1930s. It had sterling. It had black. Not a two-tone, just awesome obsidian black. The rustication is also amazing, less like a rough chunk of coal, more uniform yet quite inviting.

XL339 Rocky Donegal (HM 1981)

By 1981, the Donegal had changed from its spectacular 1979 look. The 1981 technique used the more familiar dark burgundy-brown finish and harkened back to the Early Republic examples. It’s a great look and a great feel.

XL Rustic [Mark Twain] (1981-84)

I never liked the original Mark Twain rustic. It always had that machine-cut look to it, at least to me. Then at the 2019 Chicago show, a Saturday morning dealer had three XL Rustics, all NOS. I thought, “What the fridge?” and had to take it to the light to get a better look. It was the Mark Twain, fitted with the domed ferrule and the wide-shoulder Comfort P-Lip. When I got it home, I thought it looked somewhat like a later Donegal. It’s got some “sharp” to the cut, by which I mean that your thumb catches on it in spots. Just lovely. I decicded to give it some luster with Paragon Wax, which curiously in the photo (but not to my eyes) brought out salmon colors up on parts of the bowl. It looks better in real life.

309 Premier Rustic (HM 1984)

While some of my friends don’t care for this type of rustication, I like it. It is fairly uniform, but it also has a Black Forest feeling to it, at least for me, that makes me want to pull out Carl Jung’s books (he lived there) or eat Black Forest Cake (who doesn’t like chocolate cake with cherries?) or listen to Bach (who also lived near there). . . . It is made by hand as close examination reveals, and we can actually date it, thanks to it being a Premier System—the Celtic “T” being 1984.

House Pipe, c. 1984 (Scott Forest Collection)

This House Pipe has what looks to me to be an almost identical technique with the 309 Premier above it, and is moreover one of the ultra-rare Peterson Tanshells, seen only recently in the Tanshell Spigot Special House Pipe release. While it is a nickel-mount, 1984 as approximate date of manufacture seems right, as the House Pipe had gone through its first cycle by that year (meaning that all the smooths had been exhausted, leaving the lower-quality bowls for blasting or rustication). For my part, I’d love to see more tanshell finishes, especially on sandblast and rusticated pipes.

Pebble Rustics: Connemara System (HM 1987), Dublin Millennium (HM 1988) and Baskerville (HM 1989)

The famed Pebble Rustic finish appeared about 1985 and continued through the transition from the Late Republic into the first years of the Dublin era, c. 1995. As you can see, this deep, craggy, rolling rustication was reserved for Peterson high grades, and for my money remains the finest sustained rustic finish in K&P history. According to the craftsmen I interviewed in Sallynoggin in 2013, these were outsourced to an artisan in the UK. You’ll find Pebble Rustic on the Connemara System, Dublin Millennium, Patent Lip Commemorative, Handmade and Sherlock Holmes pipes made during these years. I’ve got to say that I hope in time we may see an upper tier of rustication again on our Petes.

DUBLIN ERA (1991-2018)

Things took a slow, steady downturn for K&P’s rustication during the Dublin era, perhaps because the company was run by non-smokers at this point, who didn’t routinely pick up and smoke a Donegal Rocky and so understand its great appeal to so many pipemen. For the first dozen or more years, however, the Donegal Rocky, while not as striking as it was in 1979, maintained great consistency in its rustication and stain and was promoted as an important upper mid-grade line, as indicated by its sterling band and P-Lip with F/T option. This is the classic Donegal most of the Pete Geeks of my generation have smoked and loved.

Dublin Era Donegals: the rare A3 (HM 1999) & B2 (HM 2001) shapes

Here are two of my favorites from the classic years, when the Donegal Rocky utilized the sterling Maker’s Mark “K & P” in shields: an A3 hallmarked 1999 from the “1909” System of the 1995 Antique Collection, and the B2, one of the greatest “Irish design language” shapes hallmarked 2001.

B7 Donegal Rocky, nickel band, c. 2012

The Donegal seemed to maintain its aesthetic sensibility through the first decade of the 20th century. By the second decade, however, the rustication had become shallower, as you can see in this B7. Whether done in-house or outsourced I couldn’t say. It utilized a nickel band, slightly and a F/T.

X221 Donegal Rocky, c. 2015

By the middle of the second decade, the outsourcing of rustication led to a machine-rusticated treatment sometimes called “pineapple” rustication. I’ve also heard it called by some craftsmen at the factory the thing you step in and immediately regret. Whether K&P simply ordered machine-rusticated bowls from Gardesana (one of their suppliers at that time) or some other source I can’t say, but it does have a certain “drugstore” quality to it (“drugstores” in the US being those places which traditionally sold pharamceuticals, cosmetics and tobacco products. Cheap pipes and cheap pipe tobacco used to be sold along with cheap cigars and massive amounts of cigarettes. Those were the days. . .)

“Pineapple” Rustication on a Founder’s Edition, 2015 POY

So here it is: just about as low as it could go, a distinct aesthetic decline from hand to machine rustication. This POY and the ones that followed it in 2017 and 2018 used the same process. No wonder the craftsmen in Sallynoggin were excited to bring back in-house, hand-carved rustication!

Derry Rustic B60, 2016

There was one very bright spot in machine rustication during the Late Dublin era: the first release of “Killer B” Derry Rustic in 2016. It was an inspired move at K&P, clearing out the remarkable B shapes inventory by outfitting the bowls in army mounts with striated acrylic mocha stems to accentuate the acarmel and black stain work. The pineapple effect seemed to disappear and the entire pipe become something organic and connected. I think this is because of both the color palette and the lines the eye sees: smokey wraiths along the mocha stem which funnel into the nickel of the ferrule and are transformed into the cloud puffs of the rustic pattern, all of which is heightened by the hot foil silver P on the stem.

The Derry Rustic release was a poignant moment for Pete Geeks at the time as we said goodbye to the stunning, incredible shapes of the B catalog, most of which would never again be issued. To be sure, some shapes were “quaints,” meaning unusual and/or perhaps difficult to hold, yet several were genuine extensions and expansions of the Peterson design language and said “Kapp & Peterson” as well or better than a number of older shapes from the catalog. A testament, perhaps, to the powerful hold of this first release and the B shapes: you rarely see them on eBay.

Select photos courtesy

Scott Forest and Smokingpipes.com

Dr. Bob pipe photo courtesy Blue Room Briars

(You can read about the making of Larry Gosser’s

(You can read about the making of Larry Gosser’s

Of Pipes & Men under the BOOKS tab at the top of the blog.)

Coming Up:

Rustication at K&P, Part 2: the Laudisi Era,

an Interview with K&P’s Rusticator Wojciech Blaszcak

and Factory Manager Jonathan Fields

1 Note that K&P didn’t pay a flat rate for a bag of bowls (even when they outsourced those), but a rate that would account for a certain number of bowls at each quality level. See Detlef Seiffert’s crucial report in an earlier post.

2 This is not to imply K&P was the first to make rusticated pipes. The oldest pipe catalog I have, a 1939 House of Windsor, has an entry for a rusticated virgin. If you can document an earlier date for rusticated pipes, please drop me a line or make a comment below.